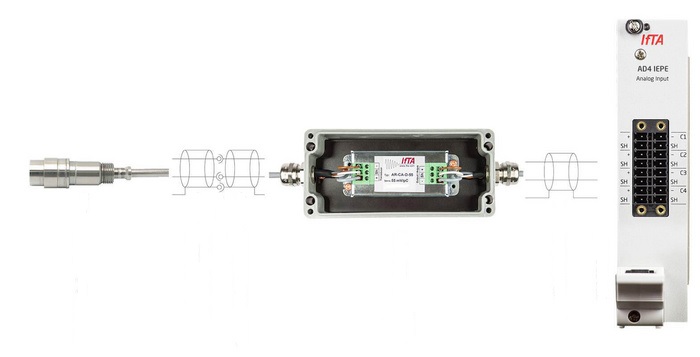

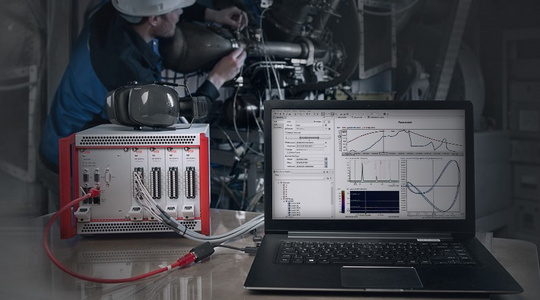

Input module with 4 synchronous analog inputs with FleXense technology.

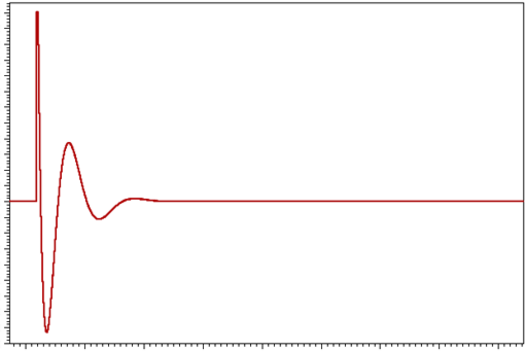

The IFTA ChargeAmplifier is used to convert dynamic charge signals into a voltage signal, which can be transmitted over longer distances to the measurement system.

Functions

- Support of sensors that deliver a charge, e.g. high temperature piezo sensors for pressure, acceleration or power

- Optionally available with certification and housing for EX na (ATEX Zone 2) applications