Application solution to measure/analyze rotor-dynamic vibrations.

Identifying Dangerous Vibrations in Production Lines

For reliable operation

The current trend in production technology tends strongly towards fully automatic and autonomous machines in line with industry 4.0. This enables companies not only to design their production more efficiently, but also to react flexibly to the needs of the market. Despite all the latest developments, basic machine elements are still to be found in most fully automatically controlled systems, since energy has still to be converted into its various forms. However, this is precisely where challenges with a wide variety of vibrations occur.

Resonance Vibrations

Potential damage in production lines

A production line represents a very complex structure of many components and thus a complex multi-mass system with different vibration modes or natural frequencies. Certain excitations lead to vibrations, for example in rollers or shafts. At a certain degree of vibration, however, malfunctions occur because the fully automated positioning systems can no longer function properly. In the worst case, these induced misalignments can lead to costly production downtimes. At the same time, vibrations may cause expensive damage to materials such as gears.

The question arises: Where does the problem result from? How can faults be corrected to ensure smooth operation?

Measurement & Analysis Technology to Prevent Dangerous Vibrations

Our solution Against harmful Vibrations in Production lines

Long-term vibration recording parallel to machine or operating data and subsequent evaluation delivers valuable information about the causes of the hazardous vibrations. On this basis, corrective measures can be taken. In the specific case of production lines, these range from improved damping over eliminating component misalignments to changing mechanical settings.

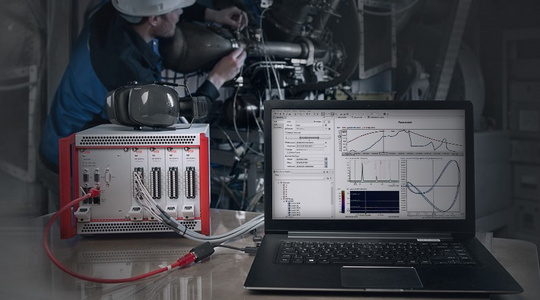

With the IFTA DynaMaster for mobile long-term data acquisition and the corresponding analysis software IFTA TrendViewer, causes can be found efficiently. The IFTA system creates transparency and an overview of large amounts of data. This enables the necessary data evaluation, which is the basis for process optimization and automation. To prevent malfunctions from occurring again, IFTA ArgusOMDS offers additional protection and permanent long-term monitoring of the plant/machine (also available as an upgrade for IFTA DynaMaster).

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.