Application solution to measure/analyze rotor-dynamic vibrations.

Early Detection and Prevention of Rotor Damage

Consistent rotational behavior - Relevance

Today, the development of gas and steam turbines tends more and more towards larger turbines with higher efficiency. At the same time, the demands placed on individual components are growing. Since there is enormous energy in the rotors of the turbines, it is very important to ensure that the rotors run smoothly. Smooth running is achieved by careful balancing and also has an influence on the service life and maintenance intervals of the turbine. The quieter the rotor runs, the lower the mechanical load on all components.

Rotor Dynamic Vibrations

Potential damage to the rotor

Rotor vibrations are primarily caused by imbalances in the rotating components, which are either caused by structural or thermal effects or are caused by damage to the blades.

In addition, resonance phenomena, the sliding bearings and the rubbing effects of the blades on the housing also trigger rotor vibrations. The reduced gap dimensions due to efficiency, however, leave little room for changes in the rotational behavior of the rotor. Small errors can lead to major damage.

Additional external excitations due to frequency fluctuations in the power network can cause torsional vibrations and thus fatigue the rotor.

Vibration Measurement Combined with Analysis and Protection

Our solution for rotor dynamic Phenomena

The installation of a vibration measurement system for complete measurement, analysis and, in an emergency, protection of the entire system through a protective shutdown. The focus should be on monitoring bearing vibrations by means of acceleration sensors. Distance measurements in the plain bearing should be used to monitor shaft and rotor vibrations. The speed and rotor position are to be measured synchronously.

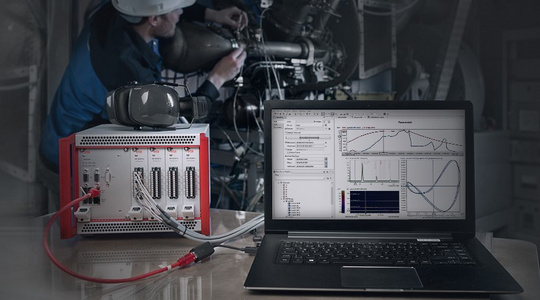

The IFTA ArgusOMDS, our all-in-one solution in combination with flexible input and output cards and the analysis software IFTA TrendViewer solves exactly these tasks. The ArgusOMDS is used in gas or steam turbines for commissioning, balancing and continuous monitoring and control. The seamless long-term storage, including the high-resolution raw data from IFTA systems, also enables the analysis of unforeseen or sporadic events. All data streams converge 24/7 in the customizable system.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.