Application solution for monitoring combustion chamber dynamics.

High Uptime and Efficiency Through Condition Monitoring

Detect Damage Early, Maintain Machines in Targeted Manner

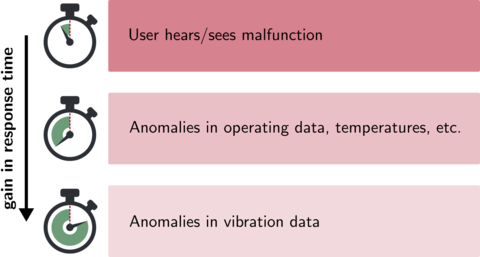

Condition monitoring is the reconstruction of the condition of a machine based on measurment data such as temperature, pressure, speed or component vibrations. Especially high-resolution vibration measurement data often provide indications of developing failures long before they lead to problems. If this data is recorded and analyzed over a long period of time, potential damage can be detected at an early stage and often even localized. This allows to plan and perform maintenances more efficiently: The service life of components can be utilized and repairs can be carried out in a targeted manner. If a damage develops very quickly, an emergency shutdown can be initiated.

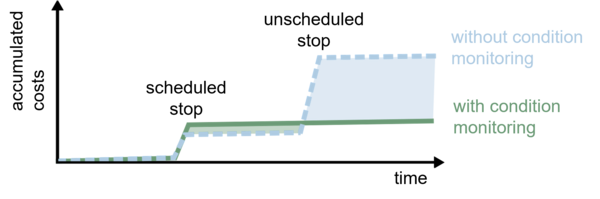

Reduce costs, increase availability

In the graphic on the left, the accumulated operating costs of a machine are schematically plotted over time, once with and once without condition monitoring. Here, the enhanced machine knowledge resulting from condition monitoring allowed the planned stop to be used more effectively for maintenance, avoiding another unplanned stop. This reduces costs and ensures high availability, which is particularly important for complex machines in critical areas of application, such as gas turbines or large diesel engines for energy supply.

COST EFFICIENCY

Reduction of downtime, utilization of component lifetimes

SECURITY

Machine protection and higher availability, as major damage is avoided

pREDICTIVE MAINTENANCE

Proactive controlled checks instead of adhoc maintenance

process optimization

Resources can be planned and ordered early

Condition Monitoring Challenges

What to measure where and how?

Identification of relevant measured variables and measurement points as well as the selection of suitable sensor technology.

Reliable Long Term Measurement

Measurement systems must run 24/7, with low maintenance and as autonomously as possible.

Handling of Large Data Sets

Robust and ideally sample-synchronous recording of all measurement and operating data in a format that allows efficient analysis of very large data sets.

High Data Quality

Ensuring consistently high data quality without gaps, incorrect sensor or operational data, changing file formats, artifacts, and the like.

Relation Measurement Data - Machine Condition

Selection of suitable methods which link the measurement data with the condition of the machine.

Integration Into Business Processes

Development of processes for the use, evaluation and improvement of the selected condition monitoring concept with the goal of optimizing the cost/benefit ratio.

IFTA Condition Monitoring Systems

our solution for combustion, torsional vibrations or rotordynamics

For more than 25 years, IFTA has been providing turnkey condition monitoring and machine protection systems for applications such as combustion dynamics, rotor dynamics or torsional vibrations. Our systems are installed all over the world and together have accumulated more than 17 million operating hours. They protect valuable and safety-critical equipment from damage, collect and record measurement and operating data in the field or on test benches, implement condition monitoring and predictive maintenance solutions, and much more. The following qualities distinguish IFTA:

- Long experience in 24/7 data recording and analysis

IFTA has always placed great importance on robust, flexible and autonomous 24/7 data recording. This means that IFTA systems and software are specialized in the acquisition and processing of large amounts of data. This is a basic prerequisite for the application of data-driven machine learning methods. - Reliable systems with long service life

Many IFTA systems are used for machine protection in safety-relevant facilities, such as power plants for energy generation. These must run reliably around the clock for periods of >10 years in sometimes hot and humid environments. IFTA products are therefore optimized towards robustness, autonomous operation and a long service life. - High level of expertise and profound consulting

Combustion dynamics is a complex phenomenon that can lead to high amplitude oscillations in a fraction of a second without much warning. IFTA combines - apart from the major OEMs - a unique expertise in this field. Applied to rotor dynamics and torsional vibrations, many of these concepts represent a genuine technological enhancement and bring in a fresh breeze of inspiration.

Recommended Products

Application solution for torsional vibrations with input module AT2.

Intuitive on-/offline analysis software TrendViewer for efficient visualization.