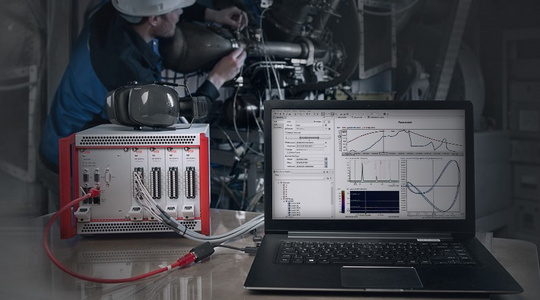

Application solution for torsional vibration measurement with timer AT2.

Engine Testing - Optimizing Operating Parameters

Test runs for the simulation of operating loads

Engine test benches make a significant contribution to the development and testing of engines. New designs are tested for a wide variety of properties. These include electrical and mechanical properties and, above all, vibration behavior under resonance loads. The requirements placed on the measurement and analysis technology are correspondingly high, especially in follow-up tests, i.e. in test runs in which the actual operating loads are simulated as precisely as possible over a longer period of time.

Precision Makes the Difference

Challenges in Engine Testing

High-resolution measurement data are essential in order to obtain optimum results from the costly test series. Especially the analysis of rotational vibrations of multiple shafts requires a precise measuring chain. In addition to the measurement technology requirements, the greatest challenge is the handling of the resulting large amounts of data. Triggered storage only makes sense if the logical condition of the trigger threshold is known. Otherwise, it is necessary to find a compromise between resolution and simplicity.

Measurement Technology for Uncompromising High-Speed Analysis

Our solution for engine testing

A measurement and analysis system that can quickly analyze high-resolution information without compromise.

The IFTA systems, in conjunction with the award-winning AT2 input module and the analysis software IFTA TrendViewer, serve precisely this purpose. They enable angle-related evaluations of torsional vibrations in real time and thus allow the optimization of important system parameters.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.