Application solution to measure/analyze rotor-dynamic vibrations.

Detect Combustion Dynamics in Burners

Optimization of Combustion Chambers

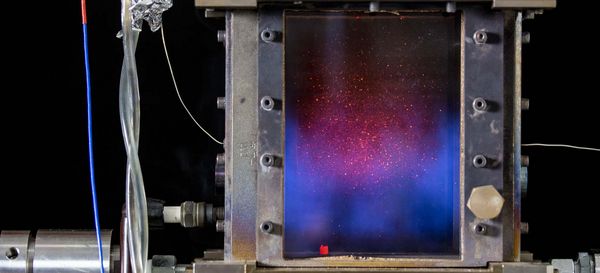

Combustion chambers are reaction chambers in which a fuel undergoes an exothermic reaction (combustion). Combustion chambers are used in many applications, such as gas turbines, rocket engines and industrial and heating plants. Therefore, the testing of combustion chamber prototypes against thermal and mechanical loads is of great importance, especially with regard to increasing efficiency. The correct parameterization of the combustion chamber and the correct mixing ratio of the fuels is the main focus of the test procedures.

Combustion Dynamics

Challenges in Burners

The primary goal of burner testing is to identify and eliminate weaknesses within the system. Above all, it is important to prevent thermoacoustic resonances or combustion dynamics by suitable parameterization of the combustion chamber. These pressure oscillations, known as combustion dynamics, combustion oscillations or thermocacoustic oscillations are often perceived as vibrations or disturbing noises. In severe cases, the components are severely damaged within a few seconds.

Measurement and Analysis Technology for Insight-Based Optimization

Our solution for burner testing

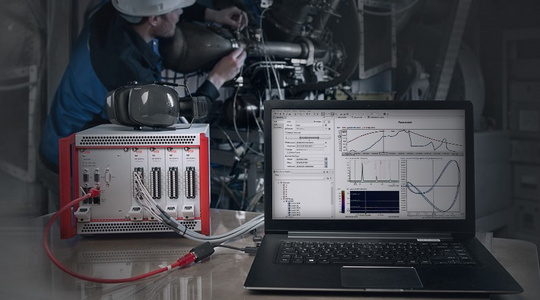

In order to meet the high requirements, it is necessary to install a measurement and analysis system that can completely identify and analyze the different types of vibrations in a burner test bench. The IFTA DynaMaster in combination with the analysis software IFTA TrendViewer provides a solution that can be perfectly adapted to any test bench. On the basis of the information obtained, valuable conclusions can be drawn about the correct parameterization of the combustion chamber.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.