Application solution to measure/analyze rotor-dynamic vibrations.

Vibration Monitoring in Hydropower Plants

HydroPower Meets Digital Transformation

Digitalization is changing our world profoundly, opening up a world of opportunities. In this era of technological change, we support you with our products and services to maximize the potential of your hydropower plants. IFTA systems combine proven experience with state-of-the-art technology to take vibration monitoring to a new level. The future of hydropower is digital - and with IFTA on your side you are well prepared to shape it.

Turnkey Solutions for Monitoring Hydropower Plants

Our systems have proven themselves in several million hours of operation in power plants worldwide and have significantly contributed to their safety and efficiency.

Safety through real-time Protection

In the world of critical infrastructure, safety is crucial. Therefore, IFTA systems feature robust real-time machine protection that can alert in advance to potentially dangerous vibration patterns. As a reaction, machines can be unloaded or even shut down in an emergency, which prevents damage and costly downtime. This not only extends the service life of the equipment, but also ensures the safety of employees.

Increasing Efficiency through Digitalization

IFTA systems stand out for their ability to robustly record high-quality data over months and years, store it in a structured manner, and visualize it intuitively. The resulting extensive data pool is an indispensable resource for making informed decisions and increasing plant efficiency.

why IFTA

The combination of proven machine protection and highly digitalized approach makes IFTA systems a unique product. Thanks to modular design, our systems adapt to your individual needs and offer seamless scalability from test bench to field application. IFTA provides innovative solutions and actively supports you as a competent partner with technical know-how.

The modular IFTA systems enable us to deploy high-quality and application-optimized vibration monitoring systems. The impressive dedication and high competence of the IFTA team provide significant added value in operating these systems. We are impressed by the team's innovative spirit, commitment and helpfulness.

Maximilian Titzschkau, Expert Data Analysis and Hydro Mechanics, Kraftwerke Oberhasli AG, Grimsel Hydro

This Has Convinced our Customers

- Machine-specific consulting

- Intuitive and user-friendly operation and configuration

- 24/7 monitoring, data recording and streaming

- Modular design, e.g. protection function can be retrofitted

- Real-time data analysis with the software IFTA TrendViewer

- AI-based anomaly detection and optimization

- Application-specific rotor dynamics functions for hydropower plant requirements

- Free sensor selection as well as integration of existing sensors

Early detection

of harmful vibra-

tions & anomalies

Data analysis

for production

efficiency

Protection for

plant availability

and safety

Profound technical

consulting

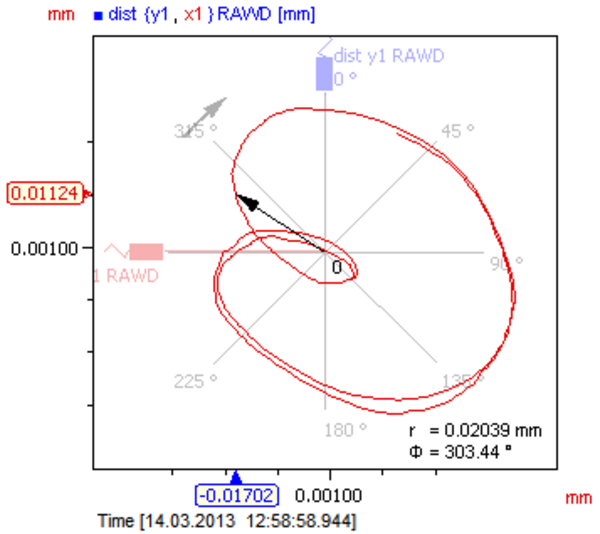

Real-Time Monitoring of Shaft Vibrations

Early detection of machine damage on rotating machines is made possible with the rotor dynamics configuration of the IFTA TrendViewer software. Deviations from normal operating behavior and damage to components can be detected at an early stage by recording and analyzing data and comparing it with historical machine data. Predictive maintenance can be initiated and planned.

Real-time signal processing

- Order-Tracking

- S-max

- Whir and whip detection

- Monitoring of torsional vibrations

Visualize your data with our plot library

Application-specific plots allow for an intuitive and fast capture of complex multi-dimensional data streams. In the field of rotor dynamics, our visualization options include the following:

- Spectrogram

- Bode-Plot

- Orbit-Plot

- Shaft Centerline Plot

Opportunities of the Digital Transformation

Digital transformation offers significant opportunities as it has the potential to improve efficiency, performance and sustainability of hydropower plants in a revolutionary way.

Increasing availability and efficiency

Digital systems enable continuous real-time monitoring of plant conditions. This facilitates early detection of deviations and potential problems, leading to more accurate diagnosis and efficient maintenance. By achieving a reduction in unplanned downtime and increasing overall equipment efficiency, it is thus possible to enhance equipment availability while simultaneously lowering operating costs.

Innovation potential

New technologies such as artificial intelligence and machine learning offer innovative opportunities to optimize performance and predict maintenance requirements.

Data-driven Decisions

Digital transformation enables profound decisions based on real-time data and analytics. Operators can base their strategic decisions on reliable, objective information, ensuring long-term success.

Sustainability

Hydropower is an important component in a sustainable energy supply. Through better control and optimization of plants, digital transformation can help to utilize resources more efficiently and as such minimize environmental impacts.

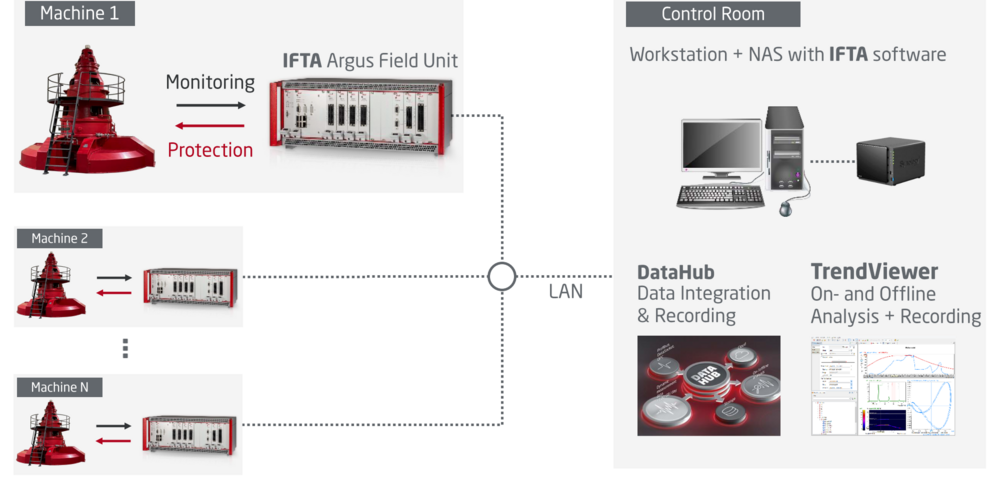

Draft IFTA Monitoring System Setup

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.