Less Emissions - More Flexibility - Increased Plant Availability

WE research for your technological benefit

Research has always played a major role in the history of the IFTA GmbH. It makes a decisive contribution to our company's success, as findings from our research are always incorporated into the development of new IFTA products and solutions.

Above all, research at IFTA GmbH provides for greener energy generation: the focus of our research is on combustion dynamics, which typically occur in gas turbines. Gas turbines are used e.g. for power generation and will continue to be needed there in the future, as power generation from renewable energy sources alone is not sufficient or flexible enough to cover peak loads and times when there is no solar/wind power generation available. Thus, new technologies and developments that make conventional energy generation more effective and environmentally friendly are also crucial for green energy. Examples for such new technologies are big data analysis or hydrogen combustion.

This is our daily motivation: With our research and our product solutions around oscillation measurements, we ensure a significant reduction of emissions and thus contribute to the protection of our planet.

IFTA GmbH Research Projects

AI for Predictive Maintenance in Gas Turbines

Efficient Machine Operation Thanks to AI

The project uses artificial intelligence for monitoring and predictive maintenance in combustion chambers of gas turbines.

Achievements: By using AI anomalies can be detected at an early stage and damage and shutdowns can be prevented by means of predictive maintenance.

Cooperation project in close cooperation withKI-Transfer Plusas well asapplied AI, funded by the Bavarian Ministry for Digitial Affairs

Runtime: March 2021 - March 2022

SensE: Combining Edge and Cloud

Sensors at the Edge

The goal of the project is to process sensor data from the edge and cloud in a collaborative manner so that the advantages (low latency at the edge, high processing power in the cloud) of the respective systems can be utilized.

Cooperation project with the Technical University Munich, Chair of Computer Architecture & Parallel Systems, sponsored by the Bavarian Research Foundation

Runtime: May 2020 - April 2023

POLKA: Combustion of Hydrogen for Energy Production

POLlutions-Know-how and -Abatement

The current POLKA project deals with combustion of hydrogen, especially with reference to thermoacoustic instabilities and flashback.

Cooperation project with several Universities and organizations under the management of the University of Keele, United Kingdom

Runtime: 2019 - 2023

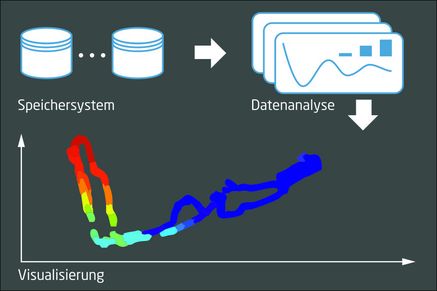

TurbO: Optimization of Gas Power Plants by Means of Big Data

Gas Turbine Optimization Using Big Data and Machine Learning

Within the scope of the TurbO project it is being investigated in which form sensor data can contribute to the optimization of plants and the development of gas turbines. The focus is put on the analysis of so far unused frequency spectra, the analysis of larger time slots and the comparison of gas turbines of the same type within one fleet.

Achievements: A new data storage concept for the IFTA DataHub

Cooperation project with the Technical University Munich, Lehrstuhl für Rechnerarchitektur & Parallele Systeme, sponsored by the Bayerische Forschungsstiftung

Runtime: September 2017 - August 2020

TANGO: Reduction of Emissions in Combustion Plants

Thermoacoustic and Aeroacoustic Nonlinearities in Green Combustors with Orifice Structures

The scope of the TANGO project comprised thermoacoustics and aeroacoustics in modern combustion systems with the goal of emission reduction.

Achievements: Patent for early warning system IFTA PreCursor

Cooperation project with several Universities and organizations under the management of the University of Keele, United Kingdom

Runtime: November 2012 - November 2016

LIMOUSINE: Optimized Plant Availability of Gas Turbines

Limit Cycles of Thermoacoustic Oscillations in Gas Turbine Combustors

The LIMOUSINE project focused on predictions and characteristics of thermoacoustic limit cycle behaviour in gas turbine combustors.

Achievements: Better comprehension of combustion dynamics and active suppression of instabilities

Cooperation project with several Universities and organizations under the management of the University of Twente, Netherlands

Runtime: October 2008 - October 2012

AI for Predictive Maintenance of Gas Turbines

How can we Avoid Gas Turbine downtimes?

In the power plant sector spontaneously occurring failures in gas turbines can result in major cost and in extreme cases even affect security of supply. In addition to the actual repair and spare parts costs, there is also a production loss and even penalties in some cases. In order to prevent this, IFTA is developing an anomaly detection system based on artificial intelligence that enables predictive maintenance. In this way, the goal is to avoid expensive downtime.

Project Tasks and Research content at IFTA

The project investigates predictive maintenance of gas turbines using artificial intelligence. The approach is that AI-based algorithms search through the gas turbine's operating information and sensor data for deviations from normal operating behavior, so-called anomalies. Contrary to established systems, there is no need to know how particular defects are indicated in the measurement data. As a result, completely new and so far unknown defects can be detected, allowing a more comprehensive and reliable monitoring. In addition, it is possible to detect defects at an early stage. This enables early action and can thus avoid unplanned emergency shutdowns and the associated high costs.

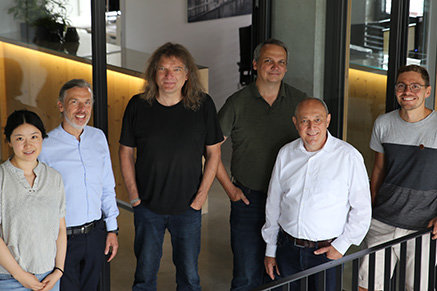

Research Team and Cooperation Partners

The project was carried out as part of the AI Transfer Plus project and funded by the Bavarian State Ministry for Digital Affairs. There was close cooperation with appliedAI - the Initiative for Applied Artificial Intelligence. The Stadtwerke München SWM provided us with recorded measurement data for this project.

Results of the research project

The project was a great success for IFTA, as by using AI any anomalies can be detected significantly earlier. Our expertise in the field of artificial intelligence could be expanded. In addition, a first prototype (as of August 2022) for annomaly detection using AI shows very good results.

Watch the video "AI in use at IFTA" on youTube

(to see English subtitles click on the settings at the right corner of the video and choose English subtitles)

SENSE - Combining Edge and Cloud

How to handle big data in the future?

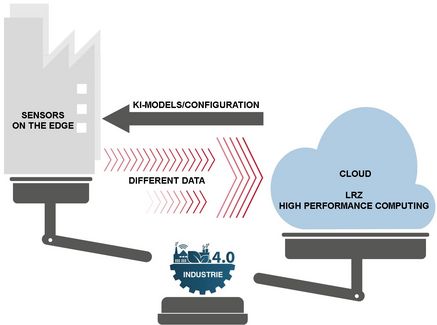

The continuous availability of system-critical infrastructure is essential for today’s society. Energy and drinking water supply systems, mobility and communications infrastructure, and many others are therefore permanently monitored with sensors. Enormous volumes of data that are generated. Analyzing it requires intelligent use of the available computing resources both on the site - close to the sensors - at the “Edge” - and in High Performance Computing systems or in the “Cloud”.

Project Tasks and Research content at IFTA

The aim of SensE is to efficiently combine all available resources for sensor data processing from the edge to the Cloud in a collaborative fashion. Its particular emphasis is on scalability and adaptivity of the sensor processing system through the intelligent coupling of system components and data.

In SensE, we aim to implement this vision: small and energy-saving systems, on site, process and analyze the locally available sensor data streams and use it in local process control loops. At the same time, the locally generated analysis results and a reduced (intelligently-selected) subset of the data are forwarded to the Cloud or to a High Performance Computing system for more complex analyses and combine data and models from multiple systems.

SensE aims to investigate the coupling of the resources, models, and data, and through this integration, an optimized sensor processing system can be developed. This system can be used on the computer systems at the edge to improve the monitoring systems and optimize the local control loops.

Research Team and Cooperation Partners

The project is carried out in close cooperation with our partner, the Chair of Computer Architecture & Parallel Systems at the Technical University of Munich, and is funded by the Bavarian Research Foundation.

From the side of the industry, the Stadtwerke München SWM GmbH in Germany contribute to obtain practical results.

Resulting Publications

- Querying Distributed Sensor Streams in the Edge-to-Cloud Continuum. Presented at the research conference IEEE EDGE 2022 in Barcelona on July 14, 2022

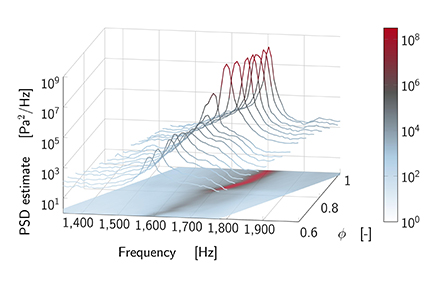

POLKA - Combustion of Hydrogen for Energy Production

Combustion of hydrogen - the future of energy production?

The combustion of hydrogen has the potential to play a key role in the energy transition. Thus, in times of overproduction, hydrogen can be produced using renewable energy sources and then in times of deficit, it can be burned in existing gas-fired power plants. One way to accomplish this is to add hydrogen to conventional fuels. However, depending on the ratio, this has significant implications for the combustion process. Compared to natural gas, for example, hydrogen has a lower energy density and a significantly higher flame speed. This results in new challenges, particularly with respect to thermoacoustic stability and flame flashback, which will be investigated as part of the project.

Project tasks and research content at IFTA

An important project goal is to further develop the early detection of combustion instabilities in gas turbines. Existing systems, such as the IFTA PreCursor, are mode-based and thus concentrate on monitoring individual, known combustion chamber modes. If hydrogen is now added to the fuel in different concentrations, it is difficult to predict what influence this will have on the relevant modes. Depending on the gas turbine or hydrogen content, a different picture is drawn. For this reason, research focuses on new early detection methods that do not require any previous knowledge of the respective thermoacoustic eigenmodes. These results should eventually lead to an extended version of the IFTA PreCursor.

This objective requires the development of resource-efficient physical models as well as the implementation of new algorithms for real-time signal processing. For the development and testing of a prototype, the already existing LIMOUSINE laboratory burner will be used. If things proceed as planned, the advanced PreCursor for early detection of combustion instabilities can already be implemented in an industrial-size combustor within the POLKA project duration.

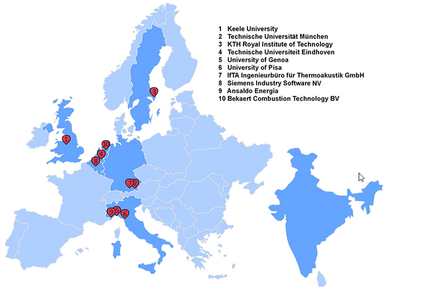

Research Team and cooperation partners

The research project consists of an international consortium of universities and companies:

Keele University, Keele, United Kingdom, TUM - Technical University Munich, Munich, Germany, KTH Royal Institute of Technology, Stockholm, Sweden, Technical University Eindhoven, Eindhoven, Netherlands, University of Genova, Genova, Italy, University of Pisa, Pisa, Italy, Siemens Energy Industry SoftwareNV, Leuven, Belgium, AE - Ansaldo Energia SpA, Genova, Italy, BEK - Bekaert Combustion Technology BV, Assen, Netherlands, IFTA - Ingenieurbüro für Thermoakustik, Puchheim, Germany

Resulting Publications

- Estimation of Dynamical Thermoacoustic Modes Using an Output Only Observer Kalman Filter-Based Identification Algorithm

Presented at the ASME Turbo Expo 2022, Paper published January, 10 2023

TurbO - Optimization of Gas Power Plants with the Help of Big Data

Data analysis for more efficiency in power supply

Gas turbines contribute significantly to the power supply. Due to their quick operational readiness, they are ideally suited to cover peak loads. However, for efficient and safe operation, such dynamic operating conditions require a specially optimized machine design along with the appropriate operating strategies. Both can only be developed and validated on the basis of a solid database of operating data, which ultimately requires continuous monitoring of the machine status and storage of the data collected in the process.

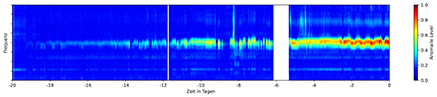

So far, one has relied on operating data with relatively low temporal resolution compared to the decisive physical processes in the combustion chamber. High-resolution dynamic sensor data, such as from alternating pressure sensors in the combustion chamber or acceleration sensors on bearings, can currently not be used due to the immense volume of data. Their collection and evaluation is simply not possible with the currently established methods. This deficit offers great potential for optimization, which will be investigated as part of this research project.

Project Tasks and Research Content at IFTA

As a first step, the research project will investigate possibilities for storing gas turbine operating data appropriately. The focus here is on finding a storage format that allows the data to be processed as efficiently as possible. In order to validate the developed concepts, about 300 TByte of gas turbine data are available, which have been recorded 24/7 with high resolution over years by IFTA ArgusOMDS monitoring systems.

Based on the newly discovered storage concept, in a second step innovative analysis algorithms will be investigated with the aim of gaining new insights into machine optimization. On the one hand, the generated data will be (pre-)processed in real-time in the power plant, and on the other hand, it will be analyzed in its entirety on supercomputers (e.g. SuperMUC). In order to present the results to operating engineers in an easy-to-understand way, research is also done in the field of visualization.

Research Team and Cooperation Partners

The project is carried out in close cooperation with our partner, the Chair of Computer Architecture & Parallel Systems at the Technical University of Munich, and is funded by the Bavarian Research Foundation.

From the side of the industry, the Stadtwerke München SWM in Germany contribute to obtain practical results.

Results of the research project

One success the team achieved was finding a new way to compress sensor data quickly and efficiently in the area of data storage. Important components of these findings have already been implemented in the development of the IFTA DataHub software.

Research work Won the Hans Meuer AWARD 2020

The research "Time Series Mining at Petascale Performance" within the TurbO project has won the Hans Meuer Award in June 2020! The Hans Meuer Award honors the most outstanding research paper submitted to the Research Paper Committee of International Supercomputing Conference.

Resulting Publications

- Time Series Mining at Petascale Performance. Presented at the International Conference on High Performance Computing. Awarded the Hans Meuer Award 2020

- Turning Dynamic Sensor Measurements From Gas Turbines Into Insights: A Big Data Approach. Presented at the ASME Turbo Conference 2019

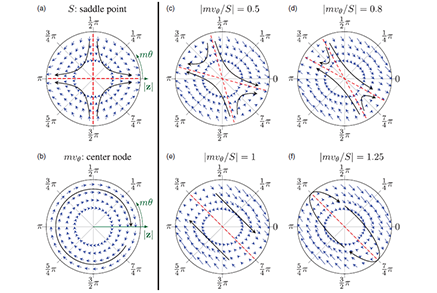

Tango - Reduction of Emissions in Combustion Plants

GREEN Combustion Techologies And Noise Control Methods

The aim of this research project is to promote the development of green and reliable combustion technologies for gas turbine power plants. One reason for motivation is the fact that modern gas turbines are susceptible to dangerous thermoacoustic instabilities due to the premixing needed to reduce NOx emissions. The other is that gas-fired power plants must be operated with increasing flexibility to compensate for fluctuating power generation from renewable energy sources, which makes their design more complicated.

Project Tasks and research Content at IFTA

The subproject worked on by IFTA within the research project comprises the development of an early warning system for thermoacoustic instability. The aim is to detect instabilities developing in the combustion chamber at an early stage, to warn the gas turbine controller and in this way to prevent the occurrence of high-amplitude pressure oscillations. The focus is on can-annular combustion systems, since these are particularly susceptible to low-frequency, thermoacoustic circumferential modes.

Research Team and Cooperation Partners

The research project consisted of an international consortium of Universities and companies:

Keele University, Keele, United Kingdom, Technical University Eindhoven, Eindhoven, Netherlands, LMS International NV, Leuven, Belgium, KTH Kungliga Tekniska Hoegskolan, Teknikrigen, Sweden, IITM - Indian Institute of Technology Madras, Chennai, India, AE - Ansaldo Energia SpA, Genova, Italy, TUM - Technical University Munich, Munich, Germany, BEK - Bekaert Combustion Technology BV, Assen, Netherlands, IFTA - Ingenieurbüro für Thermoakustik, Puchheim, Germany

Results of the Research Project

- Successful industrial implementation of a system for early detection of thermoacoustic instabilities in annular combustion chambers

- The early warning system IFTA PreCursor was filed for patent in 2015

- The research work was published as a dissertation in 2021

Resulting Publications

- In Situ Identification Strategy of Thermoacoustic Stability in Annular Combustors. Int'l J. Spray & Combustion Dynamics 10 (4), 2018

- Part-Load Limit Reduction of a Frame 9E Using a Precursor for Combustion Dynamics. Proceedings of ASME Turbo Expo, 2018

- Bifurcation Study of Azimuthal Bulk Flow in Annular Combustion Systems with Cylindrical Symmetry Breaking. Int'l J. Spray & Combustion Dynamics 9 (4), 2017

- Online Monitoring of Thermoacoustic Eigenmodes in Annular Combustion Systems Based on a State-Space Model. J. Eng. Gas Turbines & Power 139 (2), 2017

- On the Performance of Stability Margin Measures for Thermoacoustic Instabilities in Turbulent Combustion Systems. 21st Int'l Cgr. Sound & Vibration (ICSV21), Beijing, CN, 2014

Limousine - Optimized Plant Availabilty of Gas Turbines

Reducing gas turbine damage and downtime

The content of this project are so-called thermoacoustic limit cycles in gas turbine combustors. This phenomenon involves cyclic fluctuations of the combustor pressure, which can reach such high amplitudes that the gas turbine can be damaged. In order to avoid such cyclic fluctuations, a fundamental understanding of the relevant physical processes is required.

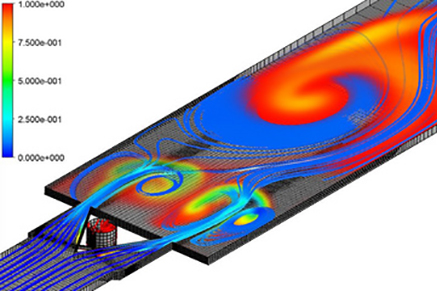

Primarily, acoustics, aerodynamics and fluid-structure interactions need to be investigated analytically and numerically. Empirical correlations between operating parameters or operating conditions and the pressure amplitudes that occur also help to identify particularly vulnerable operating points. Based on these findings, passive and active corrections can be made to the combustion process to prevent the occurrence of harmful limit cycles and thus reduce damage and downtimes of gas turbines.

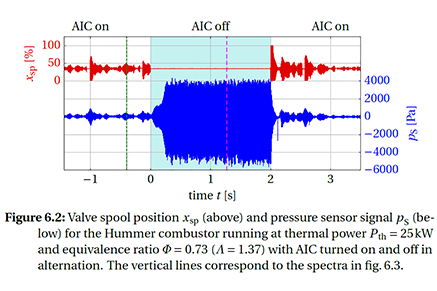

Project tasks and research content at IFTA

IFTA's aim is to reduce the thermoacoustic pressure oscillations occurring in an experimental burner system by active control intervention. For this purpose, an atmospheric laboratory combustion chamber is constructed first, which shows strong limit cycle oscillations under certain operating conditions. At the same time, a numerical calculation model of this setup is generated and validated on the basis of the experimental data.

Finally, in order to actively influence the combustion process, special valves are used which allow to control the fuel supply to the combustion chamber. By analyzing the experimental and numerical data, a comprehensive understanding of the physical processes will be gained and, based on this, an optimized controller will be designed.

Research Team and Cooperation Partners

The research project consisted of an international consortium of Universities and companies:

Sulzer Turbo Services Venlo B.V., Lomm, Netherlands, Ansys UK, Oxfordshire, United Kingdom, BRNO University of Technology, Brno, Czech Republic, CERFACS, Toulouse, France, DLR Institute of Combustion Technology, Stuttgart, Germany, Electrabel, Zwolle, Netherlands, Imperial College London, United Kingdom, Keele University, Keele, United Kingdom, Siemens Energy Power Generation, Mülheim a. d. Ruhr, Germany, University of Zaragoza, Zaragoza, Spain, University of Twente, Enschede, Netherlands, IFTA - Ingenieurbüro für Thermoakustik, Puchheim, Germany

Results of the Research Project

- Better understanding of combustion dynamics and active instability control

- Characterization of the linear acoustic behavior of a fuel valve. This acoustic description of the valve could be integrated into acoustic network models

- Determination of the relevant parameters and phenomena for the stabilization of the experimental combustion chamber with the aid of fuel fluctuations

Resulting publications

- Direct Drive Valve Model for Use as an Acoustic Source in a Network Model. Int’l J. Acoustics & Vibration 21 (4), 2016

- Control Authority Over a Combustion Instability Investigated in CFD. Int’l J. Spray & Combustion Dynamics 8 (1), 2016

- CFD-based Feasibility Study of Active Control on a Combustion Instability. In 20th Int’l Cgr. Sound & Vibration (ICSV20), Bangkok, TH, 2013

- Stability Limits and Non-linear Characteristics of a Self-excited Combustion Instability. In 19th Int’l Cgr. Sound & Vibration (ICSV19), Vilnius, LT, 2012

- Resulting Dissertation: Control Authority for Active Damping of Combustion Instabilities