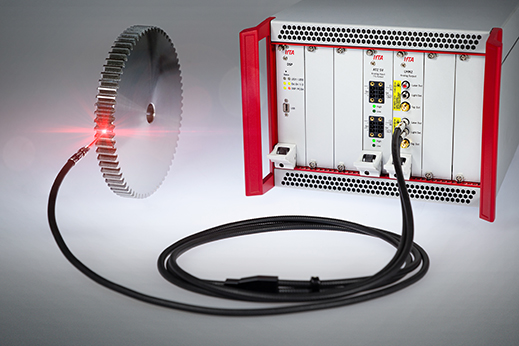

Application solution for torsional vibration measurement with timer AT2.

The LMM2 is a 2-channel module and combines one laser and one detector unit per channel for reflection measurement. Together with the signal input module IFTA AT2 High Speed Timer, it can be used as a high-precision encoder.

The LMM2 module can be flexibly integrated into mobile or stationary IFTA systems.

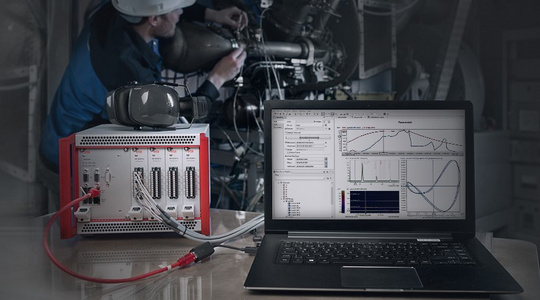

The IFTA LMM2 Standalone version is particularly recommended

- if the application requires several measuring points

- if the distance between measurement system and measurement point is > 2m

Highlights

- Laser class 1

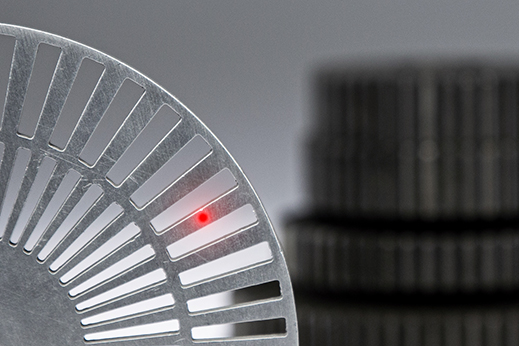

- Including bifurcated optical fiber with laser input, probe and detector output (2 m)

- Photo detector with 120 kHz bandwidth

- Analog voltage signal output in the range 0 ... -15 V

- Robust protective housing made of aluminum