Application solution for monitoring combustion dynamics.

Identifying and Preventing Vibrations in Combustion Chambers

Technical phenomena in combustion chambers

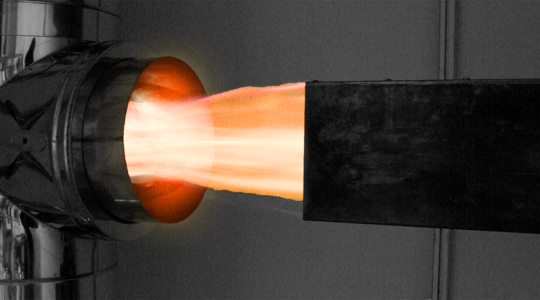

In addition to clean combustion, the challenges in the combustion chamber of a gas turbine also include the prevention of thermoacoustic phenomena. These pressure oscillations are often referred to as combustion dynamics, combustion instabilities, also called thermoacoustic instabilities, combustion dynamics, pulsations or humming. They are stimulated by the acoustic resonance frequencies of the combustion chamber and occur when the flame couples in one of these natural frequencies. Due to the high energy release, very high amplitudes of several 100 mbar can be easily reached.

Combustion Dynamics

Potential damage in turbines

These pressure fluctuations exert mechanical forces on the combustion chamber, the burner and transition pieces. Due to the very fast growing amplitudes, severe damage to the components can occur within seconds, even to the point of their destruction, making an emergency shutdown and repair of the gas turbine necessary. This leads to costly outages in electricity production, district heating and gas collection.

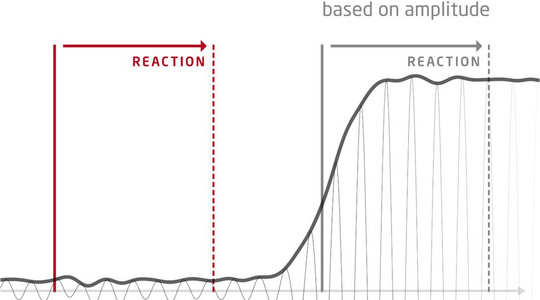

Real-Time Identification and Reaction

Our solution for combustion chambers

A monitoring system that identifies these hazardous vibrations in time, initiates protective measures and can thus prevent costly damage.

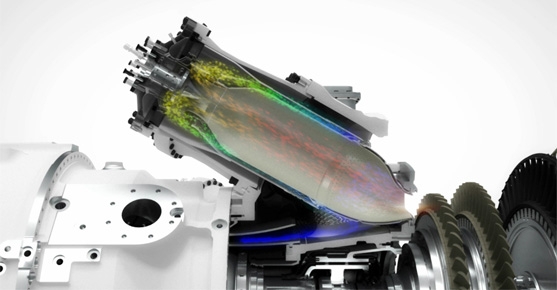

Our IFTA ArgusOMDS system solution offers solid solutions ranging from sensors to patented early detection of combustion oscillations (IFTA PreCursor) that allow safe operation of the gas turbine throughout its entire operating range. Real-time analysis with a DSP (Digital Signal Processor) ensures reliable and fast response times in fractions of a second. In addition, this also allows the operating range to be extended, i.e. a deeper reduction in the partial load range to save gas and a higher maximum load to increase efficiency, see SIEMENS Energy aSMC.

The IFTA systems are used in this environment for commissioning, tuning (summer/winter tuning) and continuous monitoring and control. Due to the continuous long-term storage including the high-resolution raw data, the analysis of unforeseen or sporadic events is also possible.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.