Application solution for torsional vibration measurement with timer AT2.

Rotational Vibrations in Turbines

Technical phenomena in gas and steam turbines

Rotational vibrations or torsional vibrations are generally defined as the vibrations of a system around a rotational degree of freedom. Thus at first linear elastic oscillations around the own body axis. Nowadays, vibration phenomena such as rotational vibrations play an enormous role in modern turbines, whether gas turbines or steam turbines. The development tends to construct ever larger turbines with a higher efficiency. Similarly, as the size and complexity of a turbine increases, so does the influence of dangerous vibration conditions on the safety of the entire system.

Net-Induced Torsional Loads

Challenges due to rotational vibrations

One of the biggest challenges in the operation of a turbine is frequency fluctuations in the grid supply, as these can promote the occurrence of forced rotational vibrations in the main shaft of a turbine. More specifically, these vibrations are caused by different fed-back induced torsional loads on the turbine, compressor and generator.

The forced torsional vibrations represent a danger precisely when their phase or operating speed coincides approximately or completely with the phase of the system's natural vibrations. In engineering, this phenomenon is called a resonance catastrophe. An undamped system reacts to even the smallest external excitation with strongly increasing oscillation deflections. The initially elastic rotational vibrations become loads that lead to the breakage of the turbine shafts.

Measurement and Analysis Technology for a Safe Operation

Our solution for protection against rotational vibrations

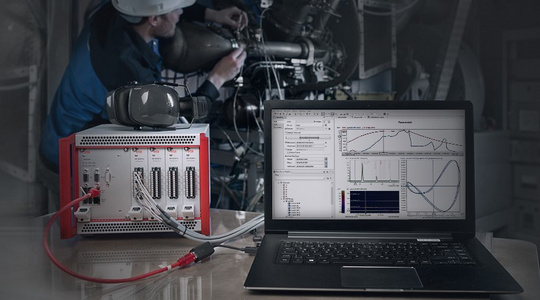

A measurement and analysis system that monitors the natural frequencies of the system and thus ensures operation outside the critical operating ranges. In critical situations, an immediate safety shutdown is initiated. This prevents costly damage and downtime.

The IFTA ArgusOMDS, our all-in-one solution in combination with the award-winning AT2 input module and the analysis software IFTA TrendViewer, meets precisely these requirements. The customizable systems enable angle-related evaluations of rotational and torsional vibrations in real time. In this way, the different natural frequencies of the torsional vibrations of the turbine can be monitored and dangerous vibration states avoided. The integrated real-time analysis immediately initiates necessary protective measures in critical operating areas.

Hands-on-knowledge: Measurement setup torsional vibrations

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.