Application solution to measure/analyze rotor-dynamic vibrations.

Early Detection of Damage in Compressors

Technical phenomena in compressors

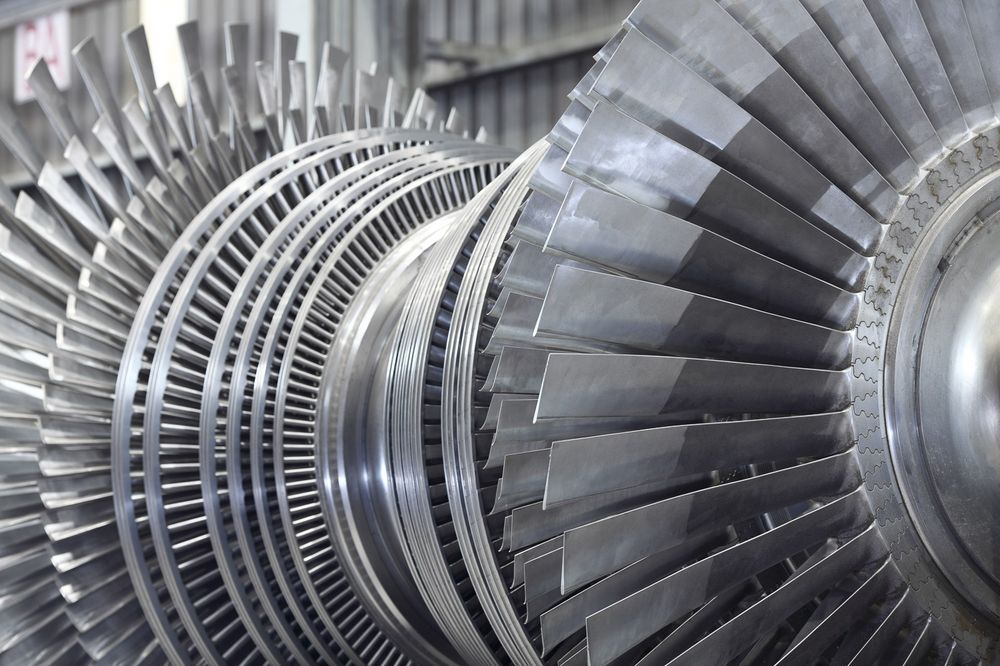

Today, gas turbines operate with a rated electrical output of up to 450 MW. This poses an enormous challenge to the material and all components of the turbine, including the compressor blades. It is precisely here that the increase in efficiency and performance is at the forefront of current developments. However, as the size and complexity of turbine components increases, so does the influence of hazardous vibration conditions on the safety of the entire system.

These vibration states are caused by cyclic loads, which in the worst case correspond to the vibration modes of the system under consideration. Known as resonance, this technical phenomenon can lead to very high vibrations.

Material Fatigue and Imbalance

Potential damage in Compressors

Over a long period of time, the cyclic loads of the compressor process and the grid-induced vibrations favor material fatigue at key points of the turbine as well as at the compressor blades.

If, in addition, the smallest imbalances exist on the rotating compressor components, the difficulties already mentioned are intensified and accelerated. Foreign bodies, such as ice chunks, can cause additional damage and thus unbalance. However, since the reduced gap dimensions due to efficiency do not allow much space in the rotation behavior of the compressor, severe consequences can occur during turbine operation. These consequences range from a reduction in efficiency to blade loss and total turbine failure.

Proactive Monitoring System for On-Time Protection

Our solution for compressor vibrations

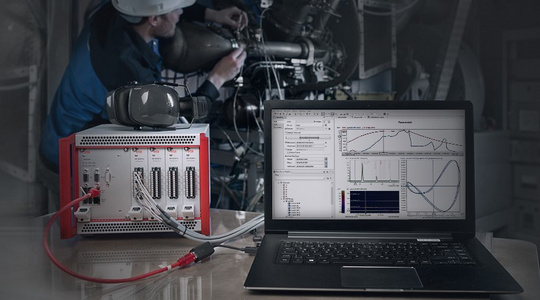

A monitoring system that identifies these hazardous vibrations in good time, initiates protective measures and can thus prevent costly damage: The IFTA ArgusOMDS, our all-in-one solution in combination with the analysis software IFTA TrendViewer.

The IFTA system offers specialized algorithms (Cepstrum, etc.) that monitor the condition of the compressor in real time and pass it on to the control system. All processes run parallel to the combustion monitoring on one hardware. The continuous long-term storage, including the high-resolution raw data, also enables the analysis of unforeseen or sporadic events.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.