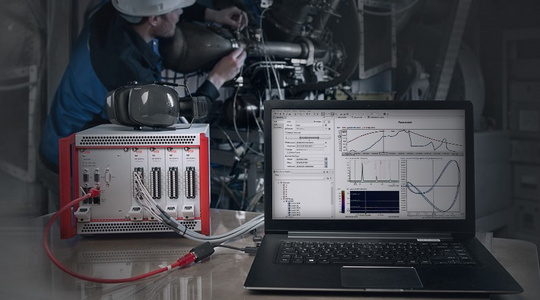

Application solution for torsional vibration measurement with timer AT2.

Vibrational Behavior of Engines on the Test Bench

Optimizing engine longevity and fuel consumption

Despite the latest possibilities to simulate and test the operating behavior of engines using computer technology methods (e.g. the finite element method), engine test benches make a decisive contribution to engine development. Especially in follow-up tests, behavior anomalies of the engine components can be directly identified and interpreted. The prevention of acoustic vibrations and rotational vibrations are the key words in this context. The results obtained serve as the basis for adapting the design parameters of the engine components and assemblies in order to optimize factors such as durability, fuel consumption and pollutant emissions. In test runs over long periods high demands are placed on precise measurement and analysis technology.

Precise Analysis of Vibration Conditions

Challenges on engine test benches

Performing test series is costly and time-consuming. For this reason, the question of cost-effectiveness is all the more important. Meaningful results from high-resolution measurement data are essential. The main challenges to be faced are the complex analysis of torsional vibrations on the one hand and the handling of the large data sets generated in the test series on the other. Rotational or torsional vibrations occur due to the acyclical force transmission of the piston movement into the crankshaft and influence the operating behavior of all downstream elements.

Uncompromising Measurement and Analysis Technology

Our Solution

A measurement and analysis system that can analyze high-resolution information quickly and uncompromisingly.

The IFTA systems, in combination with the AT2 input module and the analysis software IFTA TrendViewer, offer the optimum solution without compromise, especially for the high demands of engine test benches on measurement and analysis systems. High-resolution angle-related evaluations of torsional and torsional vibrations in real time are possible. The processing of large amounts of data is also no problem. Because on the basis of continuous data storage, no high-resolution raw data is lost and at the same time a high level of clarity is maintained by summarized data.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.