Application solution for torsional vibration measurement with timer AT2.

Ensure Operational Reliability in Large-Sized Engines

Reliability as a basic requirement for large engines

The development of large-sized engines focuses not only on fuel savings but above all on high reliability. Today, large engines are used as marine engines or in stationary applications as emergency power generators in hospitals and computer centers. In comparison to the stationary version, however, ship engines have extremely high demands on operational safety and reliability. Robust engines are required that can withstand all maritime adversities.

Vibrations in Continuous Operation

Challenges in large-sized engines

Due to the continuous operation of marine engines, great importance is attached to a long service life of the engine in order to keep operating costs as low as possible in the long term. Potential damage to the engine, for example due to rotational vibrations, results in costly and time-consuming repairs. Equally important is a high level of operational safety and reliability. Even the smallest error can have serious consequences. If the engine fails, the ship's inability to maneuver and loss of stability are potential consequences. This must be prevented. Rotational vibrations in all rotating components, such as crankshaft and propeller shaft, are regarded as technically particularly relevant causes of potential damage. Above all, the non cyclical application of force to the stroke movement of the piston causes an excitation of the torsional vibration. The use of flexible couplings is only of limited help here.

Measurement and Analysis Technology to Ensure Operational Safety

Our solution for large-sized engines

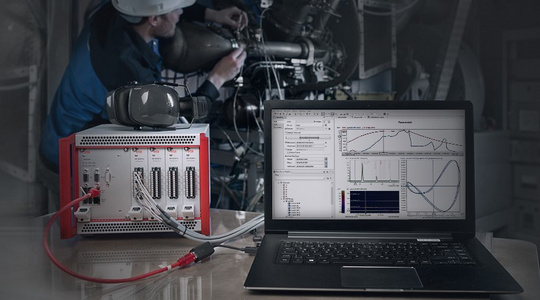

A monitoring system that identifies dangerous vibration conditions ahead of time and initiates measures to protect the engine before serious damage occurs.

Our system solution, the IFTA ArgusOMDS, in combination with the high-resolution AT2 input module and the analysis software IFTA TrendViewer, offers individually adaptable solutions for the safety of large engines. It enables angle-related evaluations of rotational and torsional vibrations in real-time. Based on excellent handling of large amounts of data, such as those generated in long-term measurements of continuous motor operation, critical vibrations can be identified and measures taken to protect the motor.

Recommended Products

Fast & intuitive online/offline analysis software for efficient visualization.